- About Us

- Sustainable Innovation

Inspired by our commitment to provide value beyond ingredients, we leverage our pioneering biotechnology and scientific expertise to fuel sustainable innovation that drives the future of human nutrition, while respecting the resources supplied by nature.

We believe in challenging the status quo. And we never stand still.

We’ve pioneered several game-changing omega-3 innovations, but we still always ask: “What’s next?”

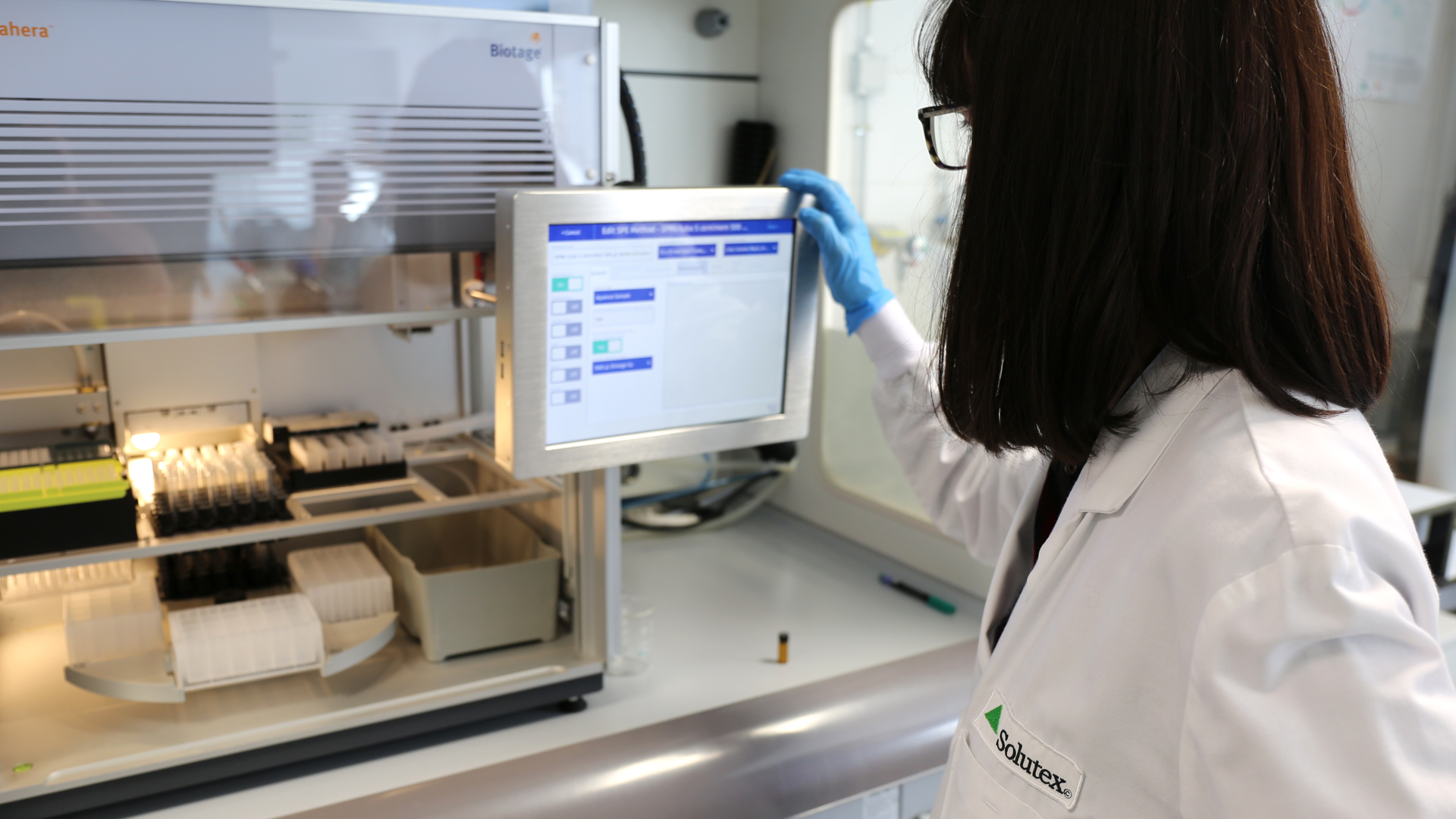

Our manufacturing operations center around supercritical CO2 technology, which gently separates EPA from DHA to create premium algae and fish oil omega-3 ingredient concentrates. A technology platform operating under the rules defining green chemistry, it does not use organic solvents, harsh chemicals, high temperatures or aggressive conditions. Plus, our sustainable operations follow a circular economy model with zero waste.

In an industry-first, our world-leading omega-3 experts identified the presence of mono-hydroxylated fatty acids in fish oil. This discovery subsequently led to the pioneering extraction, purification and characterization of a fish oil concentrate standardized in mono-hydroxylated Specialized Pro-Resolving Mediators (SPMs) that promote the natural resolution of inflammation in the body.

Licensing Harvard University’s patent for Maresins, Solutex is currently developing a pharmaceutical ingredient application from SPM Maresins 1, a potent immunoresolvant.